Gas Engine treatment: 4 – Stroke – 250 cc - 600 cc

x1 250ml

Gas Engine Treatment: 4-Stroke

This Enviro-Save Metal Treatment product is specifically designed for 4-stroke Gas Engines only (including propane and natural gas), such as: automobiles, trucks, forklifts, inboard and outboard motors, motorcycles, lawn mowers, ATV’s, RV’s, commercial and industrial engines, etc. The treatment is formulated for “4-stroke gas engines” and consists of micro-resin in technically formulated cleaners. The treatment is formulated and proportioned for the crankcase and fuel system/top-end of 4-stroke engines to ensure that the cleaners and micro-resin is distributed to all lubricated friction bearing surfaces, where it becomes impregnated into the bearing surface asperity. Improved performance and numerous other benefits from using the treatment are often noticed immediately. The inert resin treatment also affords excellent protection to bearing surfaces against corrosion and moisture, which is very important during off-season storage.

Crankcase Treatment

This proprietary Enviro-Save treatment consists of micro-resin and two cleaners:

1) A cleaner that disperses after about 1 ½ hours of normal operating time, and

2) A proprietary cleaner that remains in the engine and continues to clean the engine internally until the next oil drain and filter change.

Through friction, metal-to-metal contact and/or oil pressure, the micro-resin treatment is impregnated into all the lubricated friction bearing surface asperity and one treatment lasts indefinitely, proven by scientific oil sample analysis reports over 400,000kms or 250,000 miles.

Fuel System / Top-End Treatment

This proprietary Enviro-Save treatment consists of micro-resin, and a very high quality cleaner that is specifically formulated to thoroughly clean and treat friction surfaces in:

1) Fuel injectors, fuel injection / carburettor systems, and

2) Intake, exhaust valves, engine piston and cylinder top-end.

To receive the ultimate benefits and fuel savings use an Enviro-Save Powertrain Protection kit.

Engine Crankcase Treatment Application Instructions

Apply only with new or recent oil change on full mark. Invert container(s) and shake vigorously for minimum 15 seconds to thoroughly disperse resin, check bottom of container to gauge sufficient agitation. In cold climates, bring products up to room temperature. Pour contents into oil filler opening on engine, then immediately start engine and operate for one hour (minimum). Continue with normal recommended oil change intervals or increase oil change intervals due to the oil being much cleaner after Enviro-Save. No matter how many times you change oil, the Enviro-Save treatment remains in the surface asperity.

NOTE: New engines should only be treated after the manufacturer’s recommended break-in period, first oil change or after oil consumption has stabilized. All engines can be treated, even those with high mileage; but for engines with over 160,000 km / 100,000 miles or in poor mechanical condition, consult Enviro-Save. If engine manufacturers recommended oil change intervals and maintenance procedures have not been followed, then consult Enviro-Save prior to treating. Enviro-Save crankcase treatment will not damage or have a negative effect on oil bath clutches in motorcycles, etc. Use only Enviro-Save Diesel Engine Treatment in diesel engines.

Fuel System/Top-End Treatment Application Instructions

Shake vigorously for minimum 15 seconds and then pour contents into fuel tank at commencement of the minimum 1 hour operating period for the engine crankcase treatment.

3 or 4 cylinder gas engines: for best results when using 125 ml (4oz.) fuel treatment, the fuel tank should not contain more than 25 L (6 gal) of gasoline.

6 or 8 cylinder gas engines: for best results when using 250 ml (8oz.) fuel treatment, the fuel tank should not contain more than 50 L (12 gal) of gasoline.

Whenever possible and for best results, run fuel tank down to empty mark prior to re-filling.

NOTE: Propane and natural gas fuelled engines require the fuel tank treatment portion to be misted into the carburettor or air-intake or into a vacuum line that comes directly off the air intake manifold, while the engine is operating at a fast idle, 700 – 800 RPM. Shake frequently during misting.

4-Stroke Engine Treatment

|

Stock # |

Engine Size |

Crankcase |

Fuel Tank |

|

159602 |

Up to 225 cc |

125 ml / 4 oz. |

20 ml / 1/3 oz. |

|

159704 |

250 cc – 600 cc |

250 ml / 8 oz. |

50 ml / 2 oz. |

|

159905 |

3 & 4 Cylinder (650 cc and up) |

500 ml / 16 oz. |

125 ml / 4oz. |

|

159806 |

6 & 8 Cylinder (up to 7.5 L / 475 cu. In.) |

1 L / 32 oz. |

250 ml / 8 oz. |

|

Over 7.5 L, - 10 & 12 cylinder Gas Engines require additional product |

|

||

Treating New 4-Stroke Gas Engines

The best time to treat a new engine is right after the manufacturer’s recommended break-in period or when oil consumption has ceased or stabilized. Almost all gas engines can be treated immediately after the first oil and filter change due to two reasons:

1) Some new gas engines are run-in / broken-in at the factory, and

2) The accuracy of today’s engine manufacturing machining operations is much more accurate than it was decades ago. When cylinders are machined perfectly round and the piston rings are machined to match, the necessity for a long run-in/break-in period is reduced and oil consumption is usually not detectable. It is very important to check the engine oil when the vehicle is on the same identical parking spot and position each time so any reduction in the oil level can be detected.

If an engine is treated when it is virtually new, the precise engineered bearing clearances and other adjustments are maintained far beyond the normal life expectancy of the engine. There are numerous reasons why these bearing clearances are extremely important to maintain. One of the most important reasons is so that optimum oil flow / pressure is maintained throughout the life of the engine. Aside from reducing friction, drag and wear, the impregnation of the Enviro-Save micro-resin smoothes friction bearing surfaces, which reduces oil turbulence and extends oil life. The life of all oil seals is also increased.

Treating Old / High Mileage 4-Stroke Gas Engines

Due to consumers striving to extend the life of their vehicles, a majority of our business comes from treating older high mileage engines and components with Enviro-Save. It is more common to notice numerous significant changes in older high mileage engines or vehicles after treatment, versus new engines or vehicles.

Most of the significant changes are accomplished by restoring lost cylinder efficiency, cleaning the piston rings and the ring lands (grooves in the pistons) thoroughly, which improves and normalizes compression. An engine with uneven compression will not operate as efficiently and will not operate in a smooth manner. This situation contributes greatly to an increase in exhaust emissions, oil burning, less fuel mileage and a reduction in horse-power and performance. The eventual sticking of piston rings is the natural demise of an internal combustion engine. The thorough internal cleaning action and resin impregnation process on the cylinder walls, pistons and piston rings permit the piston rings to move freely, providing a restored cylinder efficiency and it improves the compression seal between the cylinder wall and ring surfaces.

A simple compression test on each cylinder before and after Enviro-Save will confirm the above. If all the cylinder compression figures are low, that is an indication that the piston rings have been damaged by the engine being overheated or the piston rings are simply worn out (ie: compression should be 165 PSI. but all are around 100PSI). If the cylinder compression figures vary (ie: some almost like new and a variation on some 145, 158, 130, 162 PSI) then the compression test confirms the piston rings are sticking or are stuck in the ring lands of the pistons. It is very rare, but broken piston rings will exhibit similar variations in cylinder compression figures.

Enviro-Save is not a “cure-all-in-a-can”, so it will not repair broken piston rings or parts worn beyond their useful life. Enviro-Save engine treatment chemistry normally softens oil seals in an engine or components and the resin provides a smoother surface for the oil seal to wear on, which enhances seal performance and extends seal life.

Always check when the timing belt was last changed on used engines. If the mileage is higher than what the manufacturer states for timing belt life, we advise having the belt changed so the extension in life that Enviro-Save provides, will not be reduced.

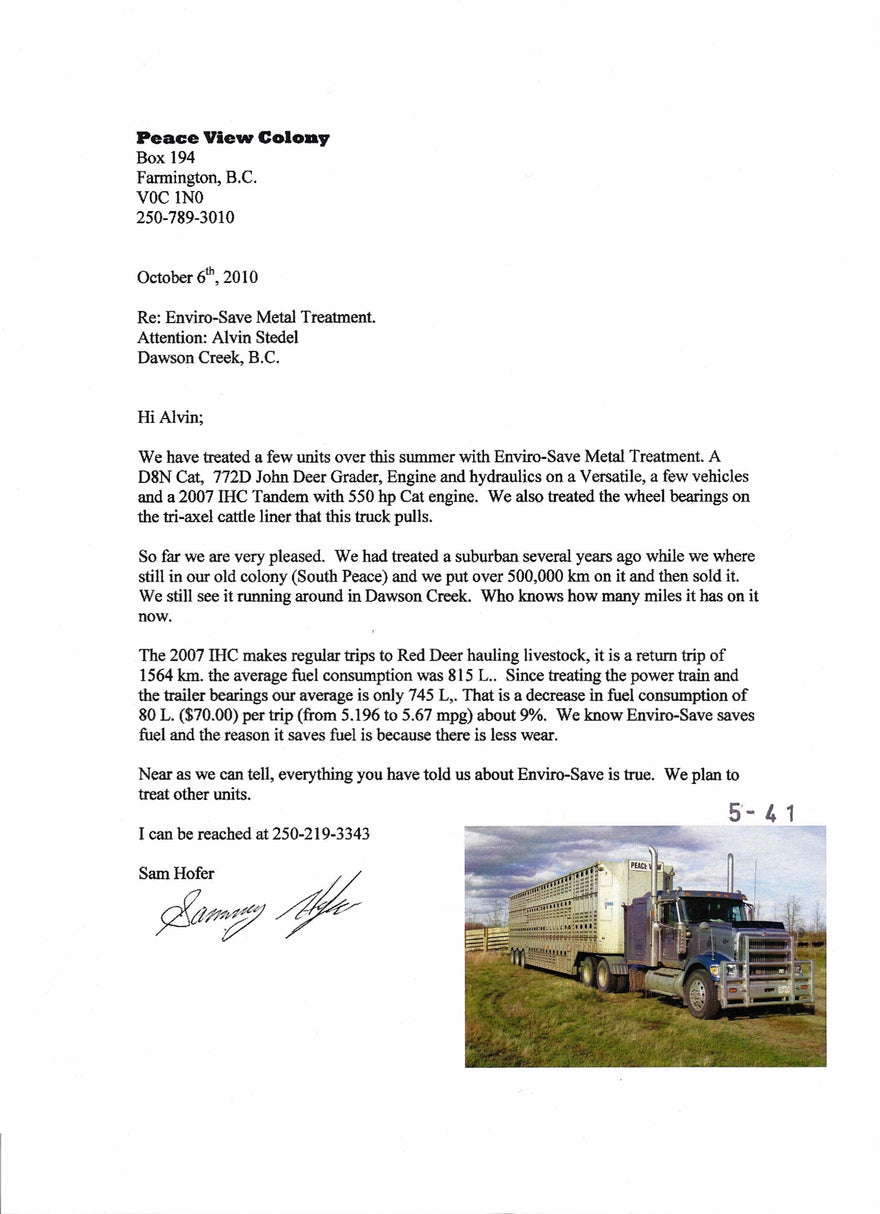

Peace View Colony Review

9% Fuel Savings

- 5.196 mpg increased to 5.67 mpg

- Fuel consumption decrease of $70 per trip or 9%

Zionsville Police Department Review

$10,000 In Fuel Savings

- A reduction of 80,000 lbs of Co2

- 1-1.5 mpg was reported by each officer

- ZERO mechanical failures

FirstBus Canada Limited Review

10% Savings

- 128-vehicle fleet

- Costly repairs could have been avoided