Our Philosophy

Why the name Envirosave? Since 1990, when the founder of Envirosave, Warren Casperson, was contemplating the company name he wanted to establish a name that reflects the priority of the product that is to be good for the Environment as well as saving people money at the pumps and minimizing mechanical breakdowns of their vehicles. For more information on Warren please see his work history at bottom of page.

Therefore ENVIROment + SAVE $= EnviroSave!

The Product

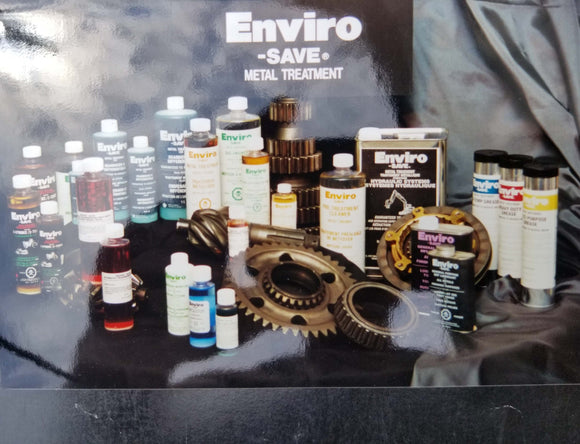

Envirosave® Engine & Powertrain Protection Metal Treatment is a unique one-of-a-kind proprietary product that imparts an ultra-low inert friction property to the lubricated friction bearing surfaces of all moving parts in engines, transmissions, differentials, hydraulics and machinery of any configuration. Unlike repetitive oil additives that are supposed to enhance oils, Envirosave® is used once and it works at the bearing surface metal level that will last for the life of your vehicle. Envirosave® only uses lubricants as a carrier and will not alter lubricant characteristics.

Our Services

Quality control of manufacturing is the most important function of our Envirosave® business and customer satisfaction is parallel. We strive to understand our customer’s activities, vehicles and equipment configurations so we are able to precisely recommend only the required products that will provide the ultimate benefits and return on investment. We assemble the “one of a kind Envirosave Powertrain Protection Kits” for all vehicles and customize kits for absolutely any type or

configuration of heavy duty or light equipment or machinery. We provide the necessary time so our customers understand what Envirosave® is, how it works and how to accurately confirm the benefits after treating components. Once we receive all the component information, we normally confirm the required product and cost within 48 hours.

Free Quotation

In order for us to provide you with accurate Envirosave® costs, we must confirm the year, manufacturer, model, engine size, number of cylinders and if a vehicle, does it have an automatic or manual transmission, front or rear wheel drive, 4 X 4 or AWD.

Diesel Engines only; due to our Diesel Engine Pre-treatment Cleaner, we need the crankcase oil capacity and engine displacement size.

The component makeup of equipment and machinery varies a lot and we need to receive or source the “Refill Lube Capacities” in order to determine size and the correct amount of Envirosave® for each component so friction, drag and wear are reduced to the maximum.

It's Guaranteed to save you money in various ways and all the results and testimony letters since 1990 provide indisputable proof of the performance and advertised claims, like no other. From the very first testimony to the latest, the excellent consistency in fuel and savings percentages and benefits from 1990 to this day are valid and repeatable.

THE 1 – AND – ONLY-Envirosave®.

No other product has the abundance of documented performance proof in so many

different applications and only 1 treatment required for life. Unheard of with so many

customer testimonies and scientific oil sample analysis results with impeccable

consistency in saving money. NO OTHER has an ROI (Return On Investment) that

runs into the 1000’s of percent over time!

ENVIRONMENTALLY FRIENDLY – GO GREEN

For prices not found on our online store please see the Price List on our original website at the LINK BELOW. Under the Prices/Quotes/Contact tab.

This price list contains most vehicles and many common equipment models, but please do not hesitate to contact us to confirm what products you require for your equipment at sales@envirosaveglobal.com