Power Steering - 55 ml / 2 oz

Hydraulic Systems

The Enviro-Save Hydraulic Treatment can be used in all hydraulic systems; from power steering, farm equipment, excavators, stationary factory equipment, to all large heavy duty hydraulic equipment including construction, industrial, marine, mining, military and offshore etc. Enviro-Save Hydraulic System Treatment provides a micro-resin impregnation for all the bearing surfaces of the hydraulic system components, including pumps, motors, actuators, cylinders, rods, valves, controls and seals etc. The Hydraulic Treatment becomes part of the metal and seal material, so that the effects and benefits are not lost when the fluid is lost or changed (unlike oil additives). In comparison to gearboxes and other machinery, Hydraulic Power Systems rely on minimal component clearances and clean oil in order to maintain maximum performance; therefore it is important to minimize metal content and wear within the system. Enviro-Save Hydraulic Treatment is GUARANTEED TO REDUCE WEAR RATES. Benefits from reducing wear are: extended equipment life, reduced component and fluid friction, less heat and cavitation, smoother and quieter operation. It is common to extend the life of hydraulic systems by two to four times the normal life expectancy after treating. It is normal for the noise level of hydraulic gear pumps to immediately be reduced. Hydraulic piston pumps create most (90%+) of their noise from the exchange of fluid within the pump and not from internal pump friction like gear pumps. Contrary to what most believe, chrome is very porous and not perfectly smooth. The Enviro-Save micro-resin impregnates the chrome surfaces, seals the surface and makes them very smooth, thus improving the sealing affect of the oil seal on the chrome and reducing contaminants entering the hydraulic system. Oil seals are also cleaned and treated, making the oil seal surface smoother and it is very common for leak down situations to be eliminated or drastically reduced.

Application Instructions

Excluding the hydraulic reservoir oil volume, the recommended quantity of Enviro-Save Hydraulic Treatment required is equal to five percent (5%) of the working volume of hydraulic oil in the system (1 L / 32 oz. into 20 L / 5 gal.).

Including the hydraulic reservoir oil volume, if only the total hydraulic fluid volume of the hydraulic system is known (including reservoir), the recommended treatment quantity is two percent (2%) of the total hydraulic system oil capacity (1 L / 32 oz. into 50 L / 12 gal.).

NOTE: It may be necessary to use additional treatment in a more comprehensive or sophisticated hydraulic system that contains an abnormal high amount of hydraulic components to hydraulic fluid ratio. Enviro-Save treatment requirements are based on bearing surface area, but due to extreme complications of figuring surface area out we established the recommended amounts over time with testing. 1) Due to the high resin content in Enviro-Save Hydraulic Treatment it is very important to check cap, invert the container and shake vigorously for 30 seconds to disperse resin prior to and during the application. 2) The Treatment should be applied to the hydraulic system while it is already operating to ensure immediate circulation.

3) Apply the Treatment in 8 equal portions and immediately operate system, with a minimum of 2 hours continuous operation time between each application.

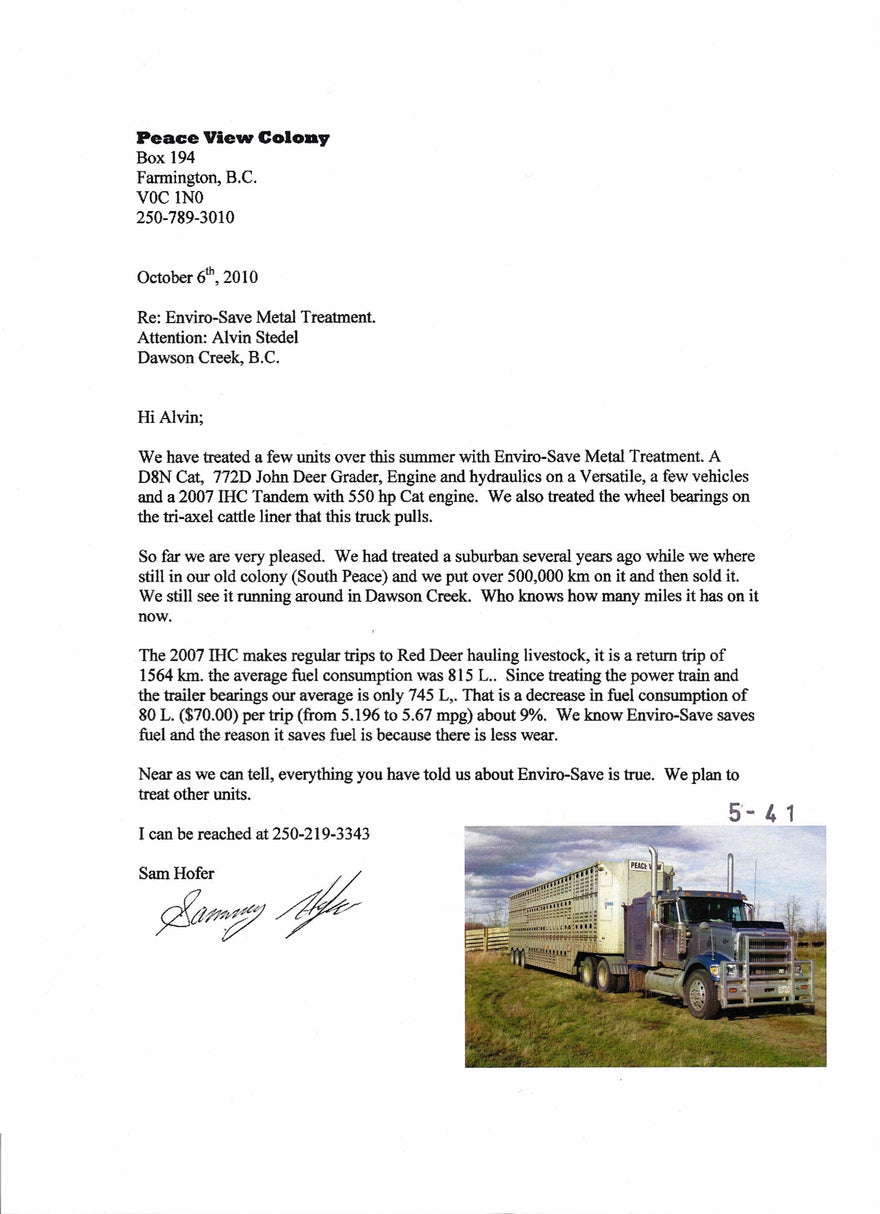

Peace View Colony Review

9% Fuel Savings

- 5.196 mpg increased to 5.67 mpg

- Fuel consumption decrease of $70 per trip or 9%

Zionsville Police Department Review

$10,000 In Fuel Savings

- A reduction of 80,000 lbs of Co2

- 1-1.5 mpg was reported by each officer

- ZERO mechanical failures

FirstBus Canada Limited Review

10% Savings

- 128-vehicle fleet

- Costly repairs could have been avoided